Supporting Specialist Automotive Projects

Boro Foundry has long supported the specialist automotive sector, delivering high-quality automotive castings for aftermarket applications and low-volume, niche components. Our expertise lies in casting complex parts using advanced materials — particularly Ni-Resist alloys, ideal for components exposed to heat and corrosion.

Award-Winning Innovation for Unimog Powerlift Arm

In 2022, we won the Casting Component of the Year Award for a powerlift arm developed for a Unimog truck. The OEM had previously fabricated the part from multiple welded sections, but this led to extended lead times and structural weaknesses. Under load, the arm was prone to cracking and premature failure.

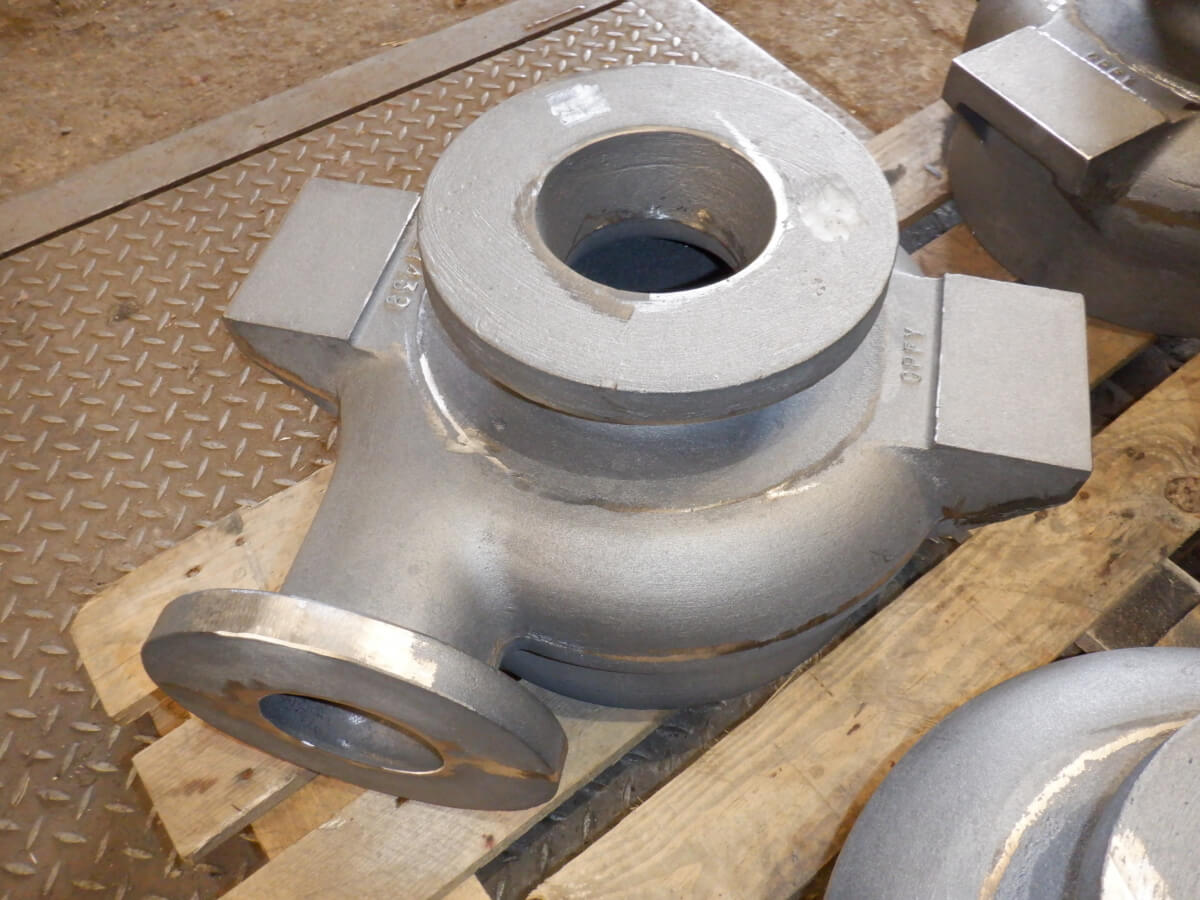

Casting for Manifolds, Turbo Housings & More

Whether you’re looking for turbo housings, manifolds, or complex one-off parts, we offer proven capability in automotive casting manufacture and material selection.

From Fabrication to One-Piece Casting

Working closely with a university partner, we helped redesign the component as a single-piece casting, selecting a superior material to enhance durability and eliminate welding. The result? A more robust part with significantly improved service life — and a dramatic reduction in production lead time.

FREQUENTLY ASKED QUESTIONS

What type of automotive castings do you specialise in?

We focus on specialist, low-volume and aftermarket castings such as turbo housings, manifolds, and complex niche components. These are typically produced in advanced alloys like Ni-Resist, ideal for heat and corrosion resistance.

Can you convert fabricated parts into single-piece castings?

Yes. We’ve helped clients redesign fabricated parts into one-piece castings, improving durability and significantly reducing lead times. This approach also removes weak points caused by welds.

What was your award-winning casting project?

In 2022, we won the Casting Component of the Year award for a Unimog powerlift arm. We transformed a multi-part fabrication into a single cast component, extending service life and streamlining production.

Do you offer support for prototyping and development?

Absolutely. We collaborate with engineers and universities to support early-stage development, material selection, and prototype production for innovative automotive solutions.

Why use Ni-Resist alloys in automotive castings?

Ni-Resist alloys are highly resistant to heat, wear, and corrosion, making them ideal for turbocharger housings, manifolds, and other high-temperature automotive applications.